What information do you need to know when renting a forklift?

When buying or renting a forklift, knowing how to choose the right forklift for the job requires you to have in-depth knowledge if you want to find the most efficient forklift for the job you need while also saving money. most cost effective. In addition to size, power source and fuel source, you need to consider and evaluate many factors that affect long-term use such as: how much the forklift can lift, how much weight it lifts, in How about sensitive cases of lifting and lowering loads and the most important thing is still in which area do you use the forklift? Should you buy or just rent to use?

With newer forklifts featuring numerous technological advancements, new ergonomic designs and even the smallest adjustments can save operators time, while promoting reduced productivity. reduce costs in business operations.

Buying or renting the right forklift is extremely important for your business. It affects everything from operating costs, productivity, employee morale, and warehouse management. There are many types of forklifts available and each is designed to be used for specific jobs. To find a good, suitable forklift, you can rely on each specific factor as follows:

Application

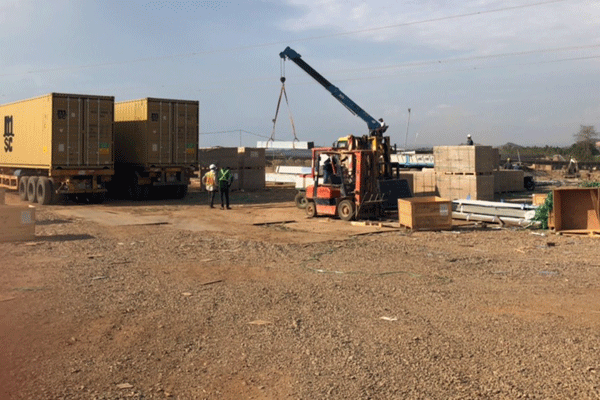

The most important factor in choosing the right forklift is your specific spec details and intended application. Are you considering whether the forklift you are buying or renting will work indoors or outdoors, or both? Will the forklift primarily operate on smooth floors or on rough terrain? What is the maximum lifting height? What kind of goods or materials need to be lifted?

On the market, there are many manufacturers and thousands of different forklift models, to choose the right one among the countless models on the market today is not an easy thing, but it is not really difficult. The simplest way is still to assess your actual application needs, then you have narrowed down your options and found the right forklift for your job.

Selection guide:

In order to choose the right forklift, the most basic criteria are still load capacity, lifting height, fuel type, tire structure and convenient effects on the operator.

1. Load, load capacity

To avoid making a mistake when you choose to buy or rent a forklift with a maximum lift capacity less than your required lifting capacity. You need to consider the following aspects:

– What is the warehouse that the forklift is handling?

– What is your average load weight?

– What is the heaviest load you need to lift?

– What is your loading width?

When you have specific information about the type of goods, the location of your warehouse, choosing to buy or rent an efficient vehicle also becomes simple.

2. Lifting height

Knowing your required lift height is equally important and will affect the forklift’s load-carrying capacity.

There are many forklifts that can lift from 2.5 meters to 6 meters, but there are forklifts that can lift much more than that. The height of goods lifting will largely depend on the nature of the business, the size of the warehouse, the most important thing is what you intend to use the forklift for specifically.

Similar to the maximum load, you must also analyze factors related to the lifting height such as:

– What is the regular lifting height?

– What is the highest score that the forklift needs to reach?

You need to pay attention to high-altitude obstacles such as ceilings, hanging lights or some other storage equipment. Also very important is the aisle width and the collapsible height of the mast so that the forklift can be used in places like containers, garages or side warehouse doors.

3. Type of fuel: There are two common types of fuel: electricity and internal combustion fuel.

Electric Forklift

Electric forklifts operate by electric energy from the battery in the back of the vehicle, so the vehicle is usually heavy. The battery in the forklift provides enough power for a standard shift of up to 8 hours or about 5 to 6 hours in case of continuous use. The two biggest advantages of electric forklifts are that they produce no emissions – a necessity if the forklift is to be operated indoors and are highly fuel-efficient.

Of all the fuels used to operate a forklift, electricity is arguably the cheapest. But in contrast, electric forklifts have a higher initial purchase price than vehicles that use fuel such as gasoline or diesel. While electric forklifts will have a higher purchase price, the efficiency will be higher because they have a longer life and are cheaper to consume than other types of forklifts. On the other hand, it does not produce emissions, operates quietly and without noise, so it is recommended to work indoors or in cold climates. However, it takes time off to recharge the battery.

Electric forklifts are easy to operate, light in motion and have a long service life, but operating maintenance costs are often higher than those of diesel-powered models.

Forklifts use internal combustion fuel

Internal combustion (IC) engines run on a variety of fuels including gasoline, diesel, liquid propane (LPG) or compressed natural gas (CNG). The main benefit of an internal combustion forklift is its ability to operate in any environment, its capacity for weight is much greater than that of an electric forklift. Internal combustion forklifts have a higher lift range (approximately 12 metres).

The purchase price of a forklift with an internal engine is the opposite of an electric forklift. Internal combustion forklifts are cheaper to purchase than electric forklifts, but they cost more in fuel per hour of operation.

Internal combustion (IC) forklifts use compressed air or diesel fuel to operate the engine.

Pneumatically powered forklifts: with this forklift you have a choice of LPG or CNG – both are quick to refuel and have a long service life. Gas powered forklifts also have a long service life with relatively low maintenance costs. However, this type of forklift is very noisy to operate, produces emissions and requires facilities to store fuel.

Diesel Forklifts: Diesel forklifts can lift much larger loads and move faster. Diesel forklifts are recommended if the forklift is used for heavy lifting or outdoors. Diesel forklifts are generally large in size, are the most powerful forklifts, and have low operating costs while being highly reliable.

Forklift tires

Tires are another top consideration in choosing the right forklift and will largely be determined by the forklift’s operating environment. That means you’re looking for a forklift for primary use indoors or outdoors, on paved surfaces or in rough terrain. Choosing the right type of tire affects the operation and safety of the forklift.

There are three different types of tires to choose from: air, solid and cushion tires that can be made from different materials.

Inflatable tires: usually designed in heavy-duty and outdoor forklift trucks, gasoline or diesel forklift trucks with pneumatic tires have the same function as car and truck tires. Inflatable tires have tires longer and wider than cushion tires, made of rubber and filled with compressed air. Inflatable tires work well outdoors on asphalt, gravel, and even unpaved terrain, but similar to car tires, forklift tires can also puncture.

Solid Tire: The solid design makes the tire extremely durable. Solid tires won’t puncture, won’t deflate which is why they are used for many heavy duty applications, including construction sites, lumber yards, recycling centers and similar locations where there may be debris. metal, nails, and other harmful hazards in the vehicle’s work environment. This solid tire is very hard to destroy, making vehicles with this tire more expensive than air tires.

Cushioned Tires: Made of solid rubber, cushion tires are pressed directly onto the wheel and have a smaller frame and lower seat than other tires. But due to the low ground clearance, vehicles with this tire cannot be used indoors because of other obstacles around the warehouse.

xe nâng, xe nâng điện