Safety when using a forklift is often overlooked

One of the most important aspects of using a forklift is a safety issue that is often overlooked by many users.

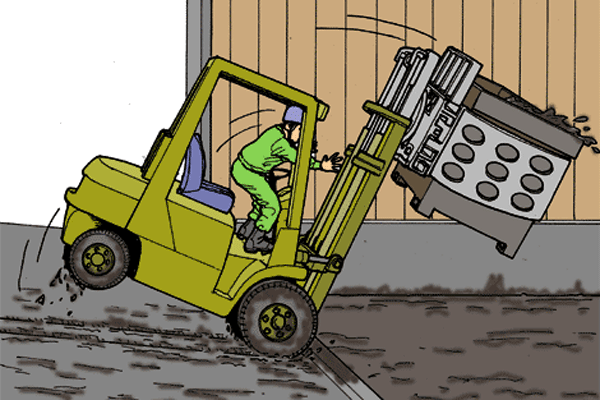

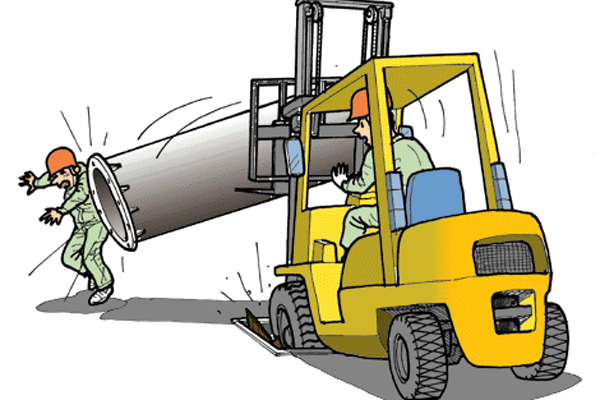

Safe use of forklifts includes many of the following: Training in operating and driving procedures, proper vehicle maintenance, proper use, regular inspection of vehicle components such as tires and lights. lighting and signals. Without regular maintenance monitoring and regular forklift inspection, accidents are more likely to occur.

- Forklift working environment – This is very important because it is important to know the terrain the forklift will be operated on, whether the vehicle will be operated indoors or outdoors, flat or rough, to choose the right tire to avoid slippery.

Operating a forklift on rough terrain may have specific requirements, such as forklift tires that must be stronger to last longer and withstand the elements of friction and adhesion. Some tires are made for forklifts for indoor use, while others are made for rough terrain or outdoor use. It is very important to choose the right one for each requirement in order to achieve high mining efficiency, great durability, safer and especially more economical if choosing the right function.

Types of Tires – There are three different types of tyres, each with its own advantages: Pneumatic forklift tires, solid rubber and polyurethane forklift tires.

Pneumatic forklift tires are ideal for heavy-duty forklift trucks and are designed for durability.

– Forklift tires made of solid rubber are the first choice for indoor forklift trucks of this type, which are prone to slippage after use because of their poor adhesion, so they are not ideal for use in areas where they are not suitable for use. rugged figure

– Finally, are polyurethane tires, commonly used for electric forklifts and specialized forklifts.

Turning radius – also known as the vehicle turning radius is the space for the forklift to work, this space will be limited by walls, obstacles in the working plane, warehouse ceiling height or any obstructions in the air differently. Turning radius – the best possible turning radius is to help the forklift work more efficiently and safely.

Is it more economical to use a new forklift or a used forklift? This is an age-old question, no one can properly answer this question because it depends on many good factors such as usage level, financial ability, chance of luck… But standing on the side of security Always use new forklifts, forklifts of big brands are always the best choice

What material source should the forklift use? Choose electric forklifts, Gasonline forklifts, diesel forklifts, this is usually based on the needs of use. For large load requirements, complex terrain, choosing forklifts using diesel fuel is optimal. Electric forklifts are more ideal for indoor operations and lighter lifting the right use the pros and cons of each model are also factors that increase safety.

Finally, people. In any area other than forklift use, working sense, the ability to understand operations as well as predict hazards will be the most important factors to improve work efficiency. work as well as minimize the possible accidents

Xe nâng cũ, xe nâng điện, xe nâng hàng