Electric, Diesel Forklift Forklift Rental In Ho Chi Minh City, Binh Duong, Dong Nai, Long An

Samcovina Joint Stock Company is an importer and supplier of used forklifts and technical services for forklifts… From the fact that the demand for rental is increasing day by day, so we open a rental service. short and long term forklifts. Forklift models we currently lease include: Container forklifts, electric pallet trucks, Reach trucks, Forklift electric forklifts.

The quality of the cars we rent are quite good, the cars are famous, all cars are carefully checked by us before selling or renting.

Our forklift rental service:

– Customers can rent the following vehicles: Reachtruck electric forklift (electric forklift with a lifting range of 6 to 12m), electric forklift Pallettruck (Pallet push-pull forklift), Forklift electric forklift (forklift line) standard electric), diesel forklift, gas forklift with a term of several months to several years.

– You do not have to pay anything other than fuel and labor costs, or you can rent in another flexible form.

– Depreciated equipment such as tires, lubricants, air filters, oil filters, etc. have been included in the rental price.

– We have a technical team that will hand over and guide you to use, as well as quickly support other problems.

– Quick support for technical issues when problems occur

– The cost is always the most competitive

Currently, we lease forklifts with the most loyal customers in Ho Chi Minh City, Binh Duong, Dong Nai, Long An and other provinces. We have factory, car park and main office in Binh Duong, and representative offices in Ho Chi Minh City, Dong Nai, Hai Phong.

Analyze the pros and cons of renting a forklift:

Advantages of renting a forklift:

– Very convenient for units with loading and unloading needs that need to mobilize more workers and equipment.

– Convenient for businesses and individuals who need to use forklifts in a short time.

– Renting a car does not cost as much as buying a car with the initial investment (quite large). Customers only need over 100 million VND to be able to rent 5-7 electric forklifts to use for production and loading and unloading purposes, costs are completely controlled. If with that budget, you can’t buy a used electric forklift.

– When renting a forklift, you do not spend much time on care, maintenance, handling technical problems and breakdowns, this has been handled by the supplier.

– When renting a forklift, it is easier to control and calculate economic costs during the leadership period. Usually, each director works in a factory for a few years and then replaces a new one. Therefore, foreign enterprises, joint stock enterprises, if the financial decision belongs to the board of directors and is responsible for business performance, renting a forklift will be much more economical than buying a forklift.

Cons of renting a forklift:

– When renting a forklift, after a rental period, the property is no longer yours.

– When renting a forklift, poor maintenance may lead to compensation for the supplier.

– Geographical location too far from the supplier leads to difficult and longer shipping and technical support.

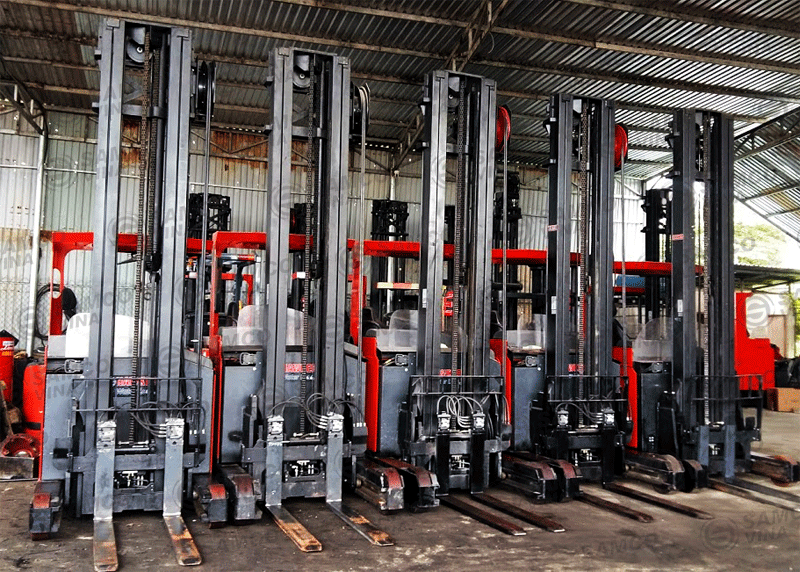

Forklift warehouse in Binh Duong

Electric forklift rental

Electric forklifts are forklifts that use the main engine to use electrical energy. Electric forklifts include: Reach truck, Pallet truck, electric forklift.

Before you decide to buy or rent an electric forklift, besides your estimates and policies, you should learn more about the advantages and disadvantages of electric forklifts:

Advantages of electric forklift:

– When operating an electric forklift, it is quite clean and quiet. Maintenance is also relatively convenient, indoor use is more convenient, no pollution, simple control, flexible handling and movement. The lifting range of this forklift is quite wide from 1.2m – 13m. Common lifting capacity from 1.4 tons to 3 tons.

– Since the maintenance intervals for electric forklift parts are much longer than that of an internal combustion engine forklift, the time required for each service is also much less than for an internal combustion engine forklift, which saves money. Significant savings in labor costs for maintenance.

Disadvantages of electric forklifts:

– Manufacturing capacity is usually smaller than diesel forklift. If there is no electricity then stop to replenish electricity, it takes 10 to 14 hours to replenish electricity, unless there are two rotating batteries, the charging time is very long.

In fact, choosing a forklift depends on the specific case you use. If you stay indoors more or use an electric forklift, it is more environmentally friendly. Nowadays, forklift technology is much more advanced. It is not true that diesel forklifts cannot operate under many demanding conditions. This depends on the vehicle type, some brands of diesel cars still work very well. So when deciding to buy or rent an electric forklift, you should be consulted.

Price list for renting electric forklifts (for reference)

| Nu | Used electric forklift for rent | Working time Number of cases/month | Rent (VND/month) |

| 01 | Forklift rental (2.5 tons) | 25 cases | 14,000,000 VND/month |

| 02 | Forklift rental (3 tons) | 26 cases | 15,000,000 VND/month |

| 03 | Forklift rental (4-5 tons) | 25 cases | 16,000,000 VND/month |

| 04 | Forklift rental (7-8 tons) | 25 cases | 18,000,000 VND/month |

| 05 | Forklift rental (10 tons) | 25 cases | 20,000,000 VND/month |

| 06 | Forklift rental (12 tons) | 25 cases | 22,000,000 VND/month |

| 07 | Forklift rental (15 tons) | 25 cases | 23,000,000 VND/month |

| 08 | Forklift rental (18 tons) | 25 cases | 25,000,000 VND/month |

Diesel Forklift Rental

Compared with electric forklifts, Diesel forklifts are used somewhat more commonly. However, it is difficult to say which one is better. Whether the use is effective or not depends on the actual situation. So let’s take a look at the analysis of strengths and weaknesses of Diesel forklifts to get an overall assessment

Diesel Forklift

Diesel forklift trucks use a diesel engine to drive, unlike electric forklifts that use batteries. They are well suited to outdoor rough terrain and various weather conditions. Although diesel forklifts are noisier than electric forklifts, they operate more powerfully and refuel them without interruption and take a long time.

– Advantages of Diesel Forklifts: Diesel forklifts do not need to use batteries and can be used 24/24, just need to add diesel oil to be used. Compared to waiting to charge a battery, simply adding more fuel to save time is crucial in high-frequency workplaces and can increase productivity. There is no need to reserve extra space for the forklift’s battery charging station, and diesel forklifts can be conveniently parked in one place. The power and performance of diesel forklifts are much stronger than electric forklifts, electric forklifts will quickly run out of battery after driving on ramps. Additional accessories added to a diesel forklift, such as hydraulic attachments, will not affect its power as much as an electric forklift. The more components an electric forklift requires, the faster the battery and total power consumption of the forklift.

– Disadvantages of diesel forklift: Due to its loud noise during work, it is not suitable for use indoors or near where workers work. Exhaust noise and toxic fumes will cause hazardous working conditions. This is a major drawback of diesel forklifts for indoor use, but there are several other downsides as well. Diesel forklifts are larger and heavier than electric forklifts, and not as useful as electric forklifts, they cannot easily or safely get around nooks and crannies. Maintenance costs for diesel forklifts are typically higher because more moving parts need to be serviced.

Price list for renting diesel forklifts by month (for reference)

| Nu | Used diesel forklifts for rent | Working time Number of cases/month | Rent (VND/month) |

| 01 | Diesel forklift (2 – 2.5 tons) | 25 cases/month | 12.000.000 VND/month |

| 02 | Diesel forklift (3 tons) | 25 cases/month | 13.000.000 VND/month |

| 03 | Diesel forklift (4 – 5 tons) | 25 cases/month | 14.000.000 VND/month |

| 04 | Diesel forklift (7 – 8 tons) | 25 cases/month | 16.000.000 VND/month |

| 05 | Diesel forklift (10 tons) | 25 cases/month | 18.000.000 VND/month |

| 06 | Diesel forklift (12 tons) | 25 cases/month | 20.000.000 VND/month |

| 07 | Diesel forklift (15 tons) | 25 cases/month | 22.000.000 VND/month |

| 08 | Diesel forklift (18 tons) | 25 cases/month | 23.000.000 VND/month |

SAMCOVINA JSC

11/26 Binh Duong avenue, Vinh Phu Ward, Thuan An Town, Binh Duong Province

Mr Hải ( Director)

Zalo, Whatsapp: +84907101899

Email: Hai.hh@samcovina.com; hoanghonghai268@gmail.comMr Huy ( Deputy Director)

Zalo, Whatsapp: +84909288633

Email: huy.dq@samcovina.comMr Học (Salesman)

Zalo, Whatsapp: +84902635491

email: hoc.hoang@samcovina.com

Xem thêm >>> thue xe nang dien | Xe nang dien

cho thuê xe nâng, cho thuê xe nâng điện, xe nâng điện

Tôi có nhu cầu mướn chiếc xe nâng 2 tấn sử dụng để di chuyển máy móc trong nhà xưởng.

Cần loại xe khỏe, không nhả khói nhiều và ồn thấp.

Xin cảm ơn

Chào Anh Huy Hùng

Vâng theo như nhu cầu của anh thì mình có thể sử dụng xe nâng điện hay xe nâng diesel mới. Anh hãy gọi lại cho chúng tôi để trao đổi thêm thông tin nhé.

Thân mến!

Công ty cho hỏi,

Bên doanh nghiệp chúng tôi có 2 chiếc xe nâng điện loại 2 tấn. Hiện tại đang ngừng sử dụng do dịch. Vậy mình óc cần phải tháo bình acqui ra để tránh hư không?

Xin cảm ơn

Chào anh Lâm

Vâng khi xe nâng điện không sử dụng 1 thời gian dài thì không cần tháo acqui ra, tuy nhiên cách tốt nhất là khoảng 1 tuần nên khởi động kiểm tra acqui, nếu hết điện nên tiến hàng xạc lại.

Thân mến!

Xe nâng dùng động cơ máy dầu tốt hơn hay dùng động cơ điện tốt hơn? Tôi cần di chuyển máy móc trong nhà xưởng.

Vui lòng tư vấn giúp

Chào anh Vũ

Vâng không thể nói xe nâng động cơ diesel tốt hơn xe nâng động cơ điện và ngược lại. Mỗi xe nâng sẽ có ưu và nhược điểm riêng. Việc chọn đúng mục đích sẽ phát huy tối đa những ưu điểm của nó.

Thân mến!

Công ty cho thuê xe nâng vui lòng cho hỏi.

Nhà xưởng công ty chúng tôi ở Tam Phước Đồng Nai. Hiện đang giãn cách và cũng đang muốn sắp xếp lại máy móc. Vậy bên công ty mình có cho mướn xe nâng tại thời điểm này được không?

Cảm ơn

Chào Anh Long

Vâng, về mảng này chúng tôi vẫn đang phục vụ khách hàng nhé. Để chúng tôi liên lạc lại với anh để trao đổi cụ thể hơn nhé.

Thân mến!

Chào công ty cho thuê xe nâng.

Xin cho hỏi, bên mình có bán loại xe nâng nào để nâng người lên độ cao trên 10m dùng để lắp thiết bị điện không?

Xin cảm ơn

Chào anh Trí

Vâng hiện tại bên công ty chúng tôi không có bán và cho thuê dòng xe nâng người anh nhé.

Thân mến!

Cần thuê xe nâng diesel tải trọng 2 tấn.

Vui lòng tư vấn báo giá.

Thanks

Vâng, chúng tôi sẽ liên hệ lại để tư vấn báo giá cụ thể cho mình nhé.

Thân mến

Cần thuê xe nâng điện tải trọng 2.5 tấn, tầm nâng 3m. Vui lòng tư vấn báo giá.

Thanks

Chào A/C vâng, chúng tôi đã nhận được yêu cầu của bạn. Bộ phận tư vấn của chúng tôi sẽ liên hệ lại để tư vấn hỗ trợ mình nhé.

Thân mến

Chúng tôi cần thuê 1 xe nâng chạy điện, tải trọng 2.5 tấn, tầm nâng 3m, sử dụng để di chuyển máy móc trong nhà máy,

Vui lòng tư vấn báo giá qua email

Thạnh

Vâng, chúng tôi đã nhận được yêu cầu của anh, bộ phận tư vấn báo giá của tôi sẽ liên hệ lại để tư vấn báo giá cho mình nhé.